Loading...

Loading...

Advanced APIT Rice Processing Technology for Maximum Efficiency, Quality, and Profitability

We are experts in APIT Rice Mill Machinery and help your business achieve operational excellence

Reduce Processing Costs

Optimize operational expenses and increase profitability with efficient machinery

Optimize Production

Efficient scheduling and maximum output efficiency with advanced automation

Avoid Technical Issues

Prevent unexpected breakdowns and reduce maintenance costs with reliable equipment

Simplify Operations

Streamline rice mill management systems with intelligent automation

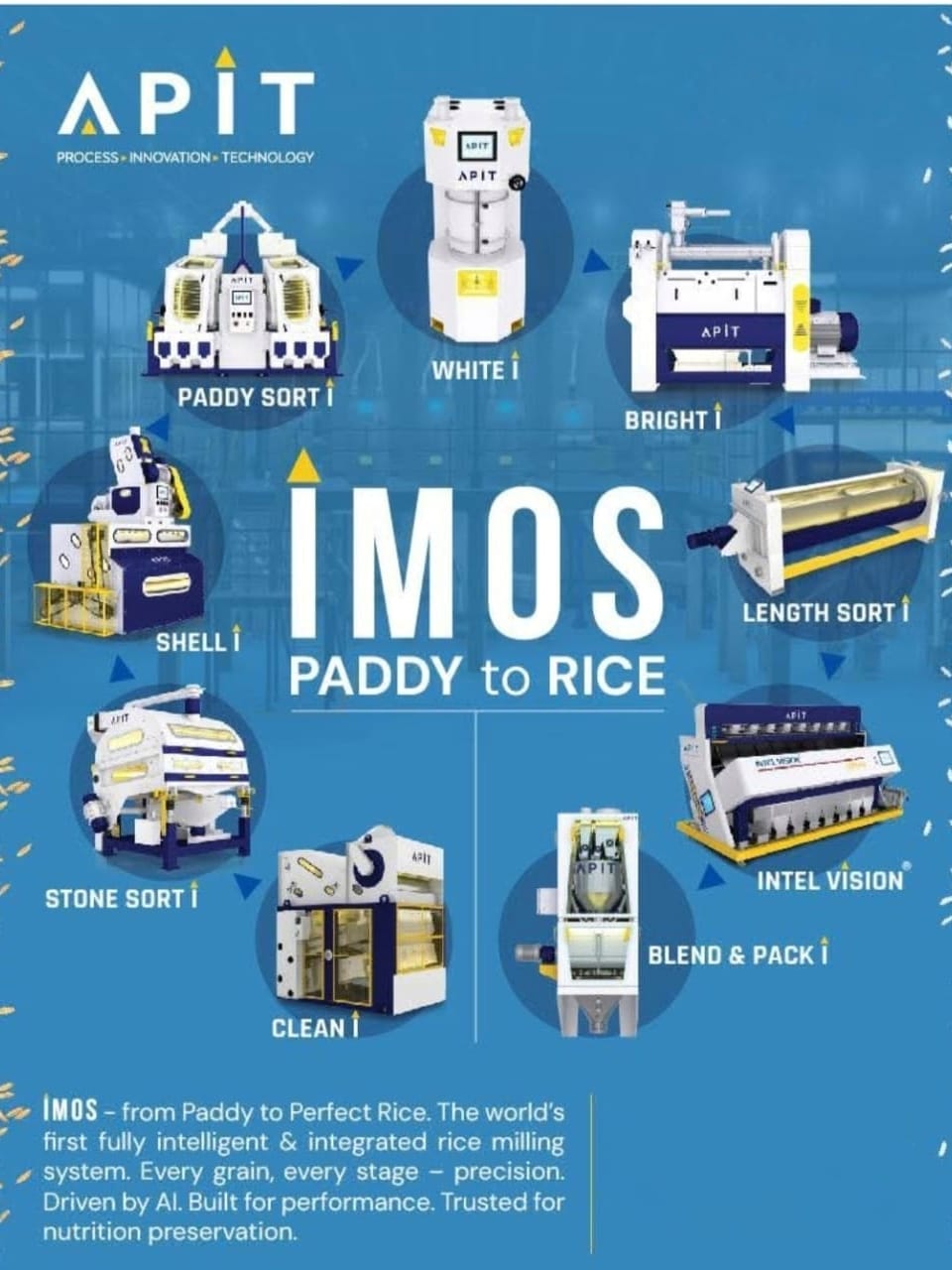

Complete transformation from raw paddy to premium quality rice with APIT technology

Raw Material Input

Polished & Graded

Remove Impurities

Nutrition Lock

APIT’s cutting-edge technology integrates Fully Automated Machinery, intelligent process control, and precision-engineered design to ensure maximum efficiency and superior rice quality.

Recipe process design driven by Artificial Intelligence with each plant customized to customer requirements.

Visualization software for process analysis, data analytics and maintenance prediction within the plant.

Energy-efficient operations with nutrition-preserving technology and reduced environmental impact.

Every machine meets highest standards of performance and reliability with rigorous quality checks.

Skilled, motivated team with customer-focused approach and continuous training programs.

Continuous R&D investment developing advanced solutions that set industry benchmarks.

Business conducted with honesty, transparency building lasting relationships based on trust.

Advanced APIT Rice Mill Machinery for Maximum Efficiency and Quality

The world's first rice milling technology that delivers precise Whiteness Index (WI) and Translucency Index (TI) while accurately predicting the Cooking Index (CI) and preserving the Nutrition Index (NI).

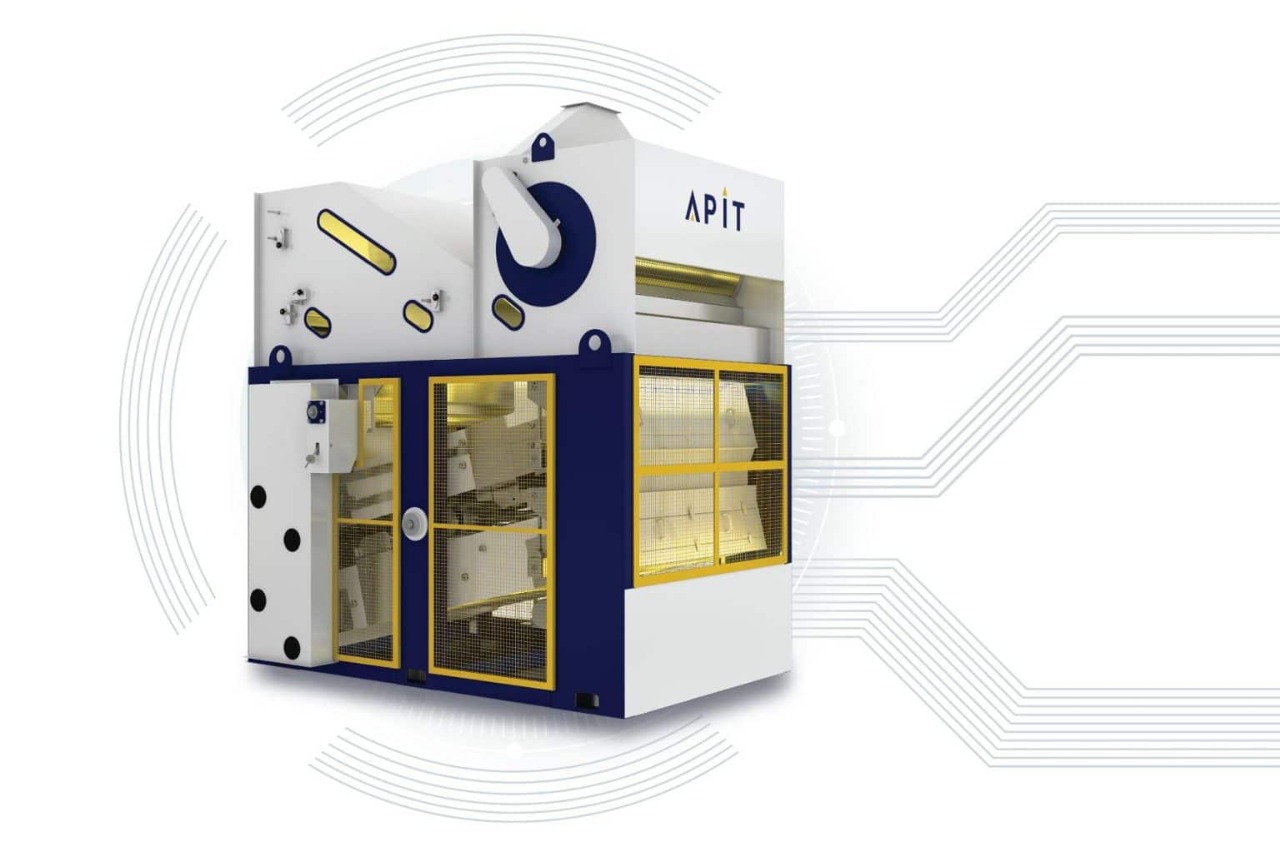

The first line of defense in rice perfection! Built specially for dusty, contaminated paddy, this intelligent pre-cleaning system removes even the tiniest impurities in a single shot.

In the world of intelligent rice milling, cleanliness is not just a process — it's a promise.

CLASS I, our new-age fine cleaning machine, gently lifts every grain, removing dusty particles and impurities with:

From dusty harvest to crystal-clear paddy, CLASS I sets the tone for happy milling.

Your grain deserves the best entrance before it transforms into excellence.

The hawk-eyed stone sorting marvel from our IMOS system. Detects and removes mud stones and mineral impurities with exceptional accuracy using gravity-based sorting.

The APIT Shell I is a highly efficient and intelligent paddy shelling machine designed to remove the outer husk from paddy and produce premium-quality brown rice. It features built-in husk separation, smart automation, and user-friendly operation for enhanced performance.

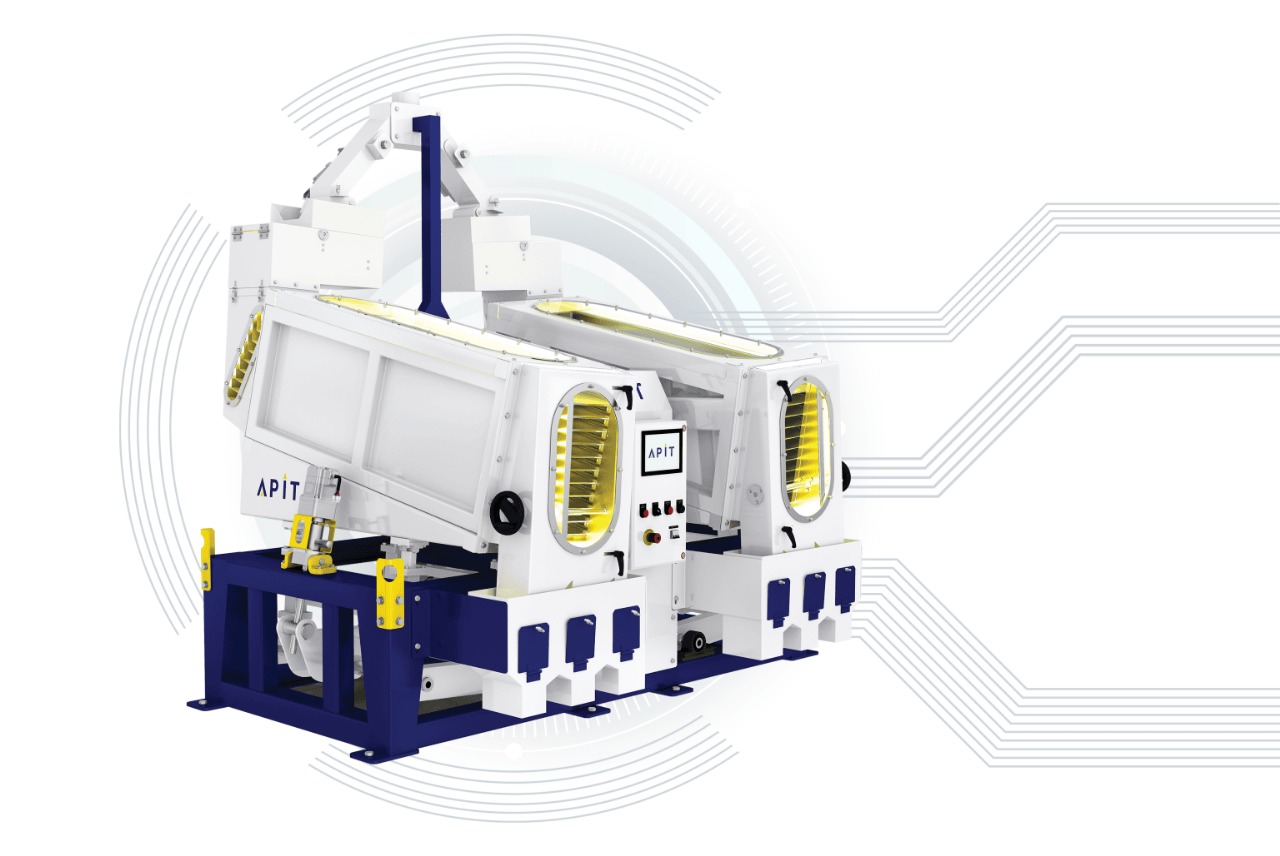

The world's first intelligent brown rice ecosystem enabler! Designed to sort husk, paddy, and deliver crystal-perfect brown rice for your next processing stages.

Precision separation of grains based on thickness using revolving cylindrical screens. Ensures uniform quality by removing oversized and undersized grains from the main batch.

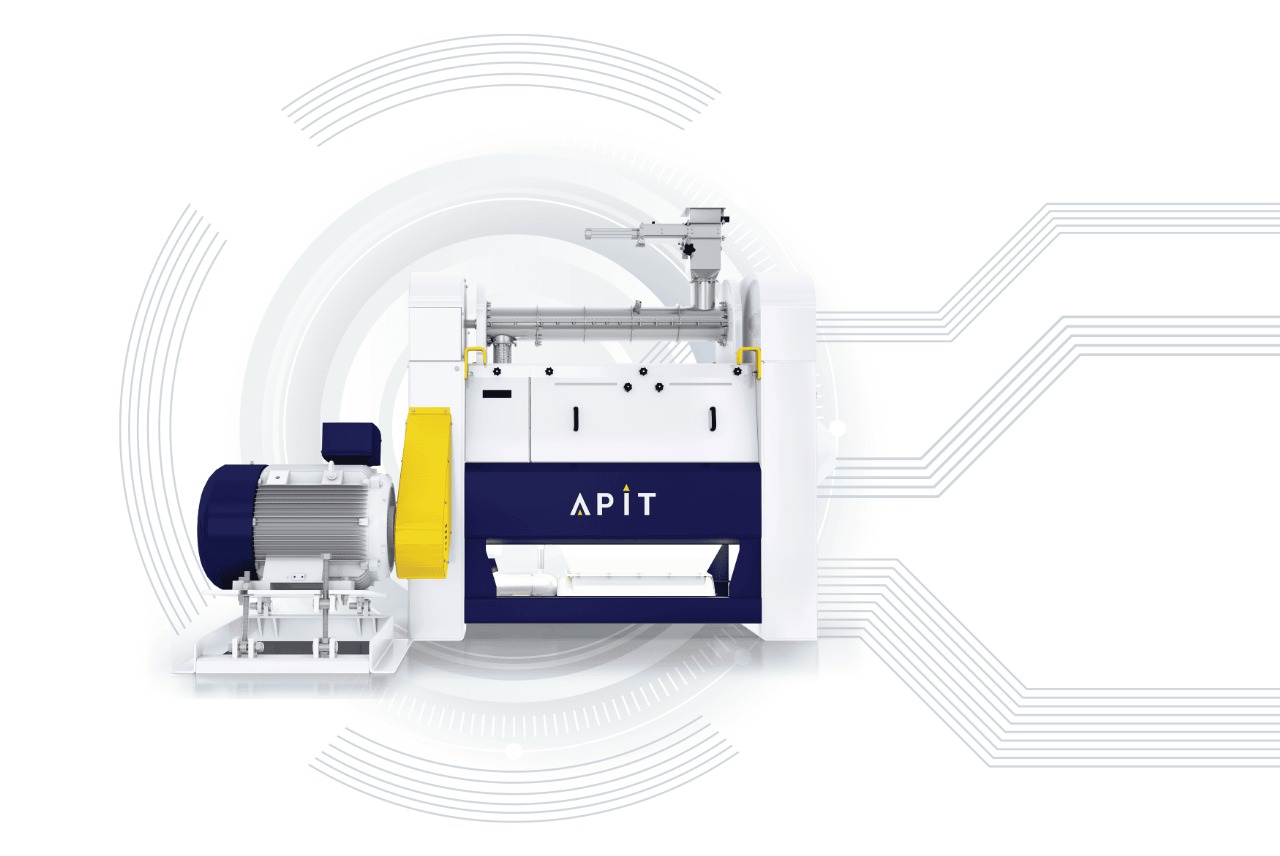

World's most intelligent digitally operated rice de-branning & friction polisher. Define your desired de-branning % and precise whiteness index with unmatched consistency.

Expertly crafted to remove the delicate layer of bran residue, transforming rice appearance for a cleaner, more polished look with stunning glossy finish.

The APIT LENGTH SORT I delivers precision grain length separation with intelligent automation and cutting-edge design. It ensures consistent performance across various paddy types—steam, boiled, or raw—while minimizing human intervention through full automation.

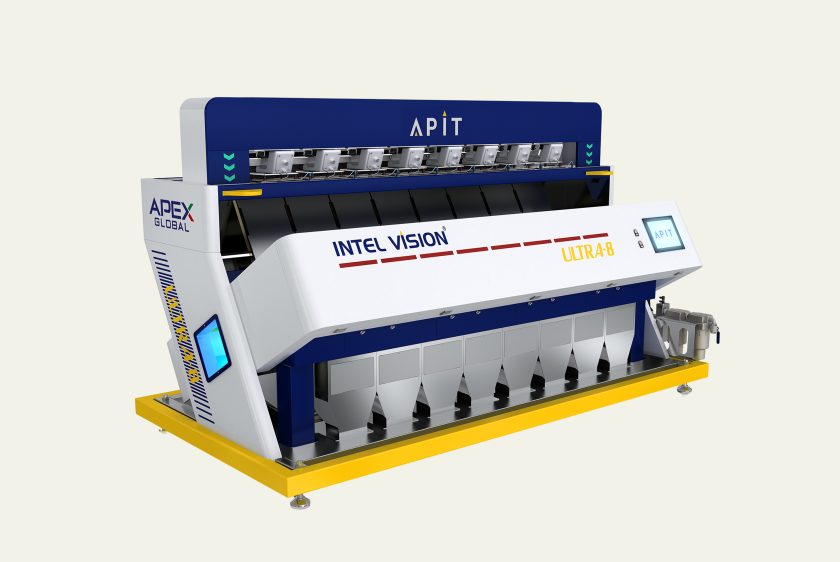

Enhances the quality of final rice by efficiently identifying and removing discolored or defective grains using advanced optical sensors and imaging technology.

The APIT BLEND & PACK I 12 combines advanced automation, superior accuracy, and intelligent process integration. It seamlessly blends and packs grains with precision while optimizing space, cost, and operational efficiency.

India's rice superpower! From manual guesswork to AI-driven automation, APIT has reimagined parboiling & drying with the world's most advanced solutions.

We take pride in offering the best-in-class Zinc Aluminium Grain Storage Silo, crafted for long-term, rust-free storage of grains. Built with high-quality zinc aluminium material, this silo ensures exceptional durability, corrosion resistance, and a lifespan of up to 40 years.

| Nos Of Sidewall Sheet Rings | 10 Nos |

| Nos Of Sidewall Sheet per Rings / Stiffeners | 20 Nos / 40 Nos |

| Sidewall Sheet | 450 GSM |

| Roof Sheet | 200 GSM |

| Stiffeners | Hot Dip Galvanized “W” type stiffener G165 (500 GSM) |

| Stiffener Dimensions | 75mm x 16.5mm |

| Sheet Corrugation Standard Pitch x Depth | 31 Deg |

| Silo Roof Angle | HDG Hex Head Grade 8.8 |

| Fastening Nuts and Bolts | Complying IS: 1363/2016 |

Specifically designed for the Rice Mill Industry, the Turbosteam Boiler stands as a symbol of reliability and innovation. With over 2000 successful installations worldwide, it ensures high thermal efficiency, fuel flexibility, and long-lasting performance.

The Paddy Dehusking Rubber Roll is engineered for high-performance rice milling operations. Designed for durability and precision, it ensures smooth, vibration-free operation and excellent shelling efficiency on both parboiled and raw paddy.

A revolutionary rice milling project that combines advanced technology with sustainable practices to deliver superior quality rice with maximum nutrition preservation.

Competitive pricing and comfortable payment schedules for company clients, easy transition to advanced machinery with complete support.

We conduct enterprise assessment and implement automated rice processing accounting systems with latest technology integration.

Expert consultation for rice processing operations with the goal of optimizing production costs and enhancing efficiency.

Comprehensive training programs for your staff and ongoing technical support to ensure smooth operations.

Regular maintenance services and readily available spare parts to minimize downtime and maximize productivity.

Jeevika Enterprises has been a pioneering force in the rice mill machinery market since 2010, delivering cutting-edge APIT solutions across India with unwavering commitment to quality and innovation.

Proprietor

Under the visionary leadership of Mr. Sunil Poratkar, Jeevika Enterprises has revolutionized rice milling technology in India. Our mission is to empower rice mill owners with intelligent, automated solutions that maximize productivity, minimize operational costs, and deliver unparalleled quality.

With over two decades of industry expertise, we bring world-class APIT technology to every corner of India, ensuring that our clients stay ahead in the competitive rice processing industry.

ISO

APIT Certified Partner

Quality Certified

Premium Dealer